9 3D Model Design: Tips and Tricks

Whether printing a model that you designed yourself or printing a freely available model from the internet, there are some important design considerations to keep in mind before printing.

In this chapter, we cover

- Appropriate design sizes & tips for large designs

- What units of measurement to use when designing your model

- Identifying overhang and print-bed contact points

Size

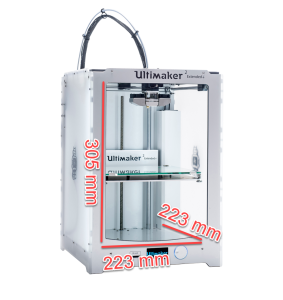

Sometimes it is difficult to determine the size of your model, but you need to know this to ensure it is possible to print on our machines. The build volume (the amount of space available to print) of the Ultimakers in the DSC makerspace is 223 x 223 x 305mm. Specifically, the print bed measures 223 x 223mm. Your design will need to fit within these dimensions.

However, 3D printing is a relatively slow process. While the Ultimakers are technically capable of printing an object as large as their full build volume, it would take a prohibitive amount of time to do so. The following are a list of estimated print-times (using the makerspace’s default settings) that should help guide your design:

| Object | Estimated print time (Ultimaker) |

Golf ball Golf ball |

1 hour and 30 minutes |

Baseball Baseball Cricket ball Cricket ball |

6 hours and 30 minutes |

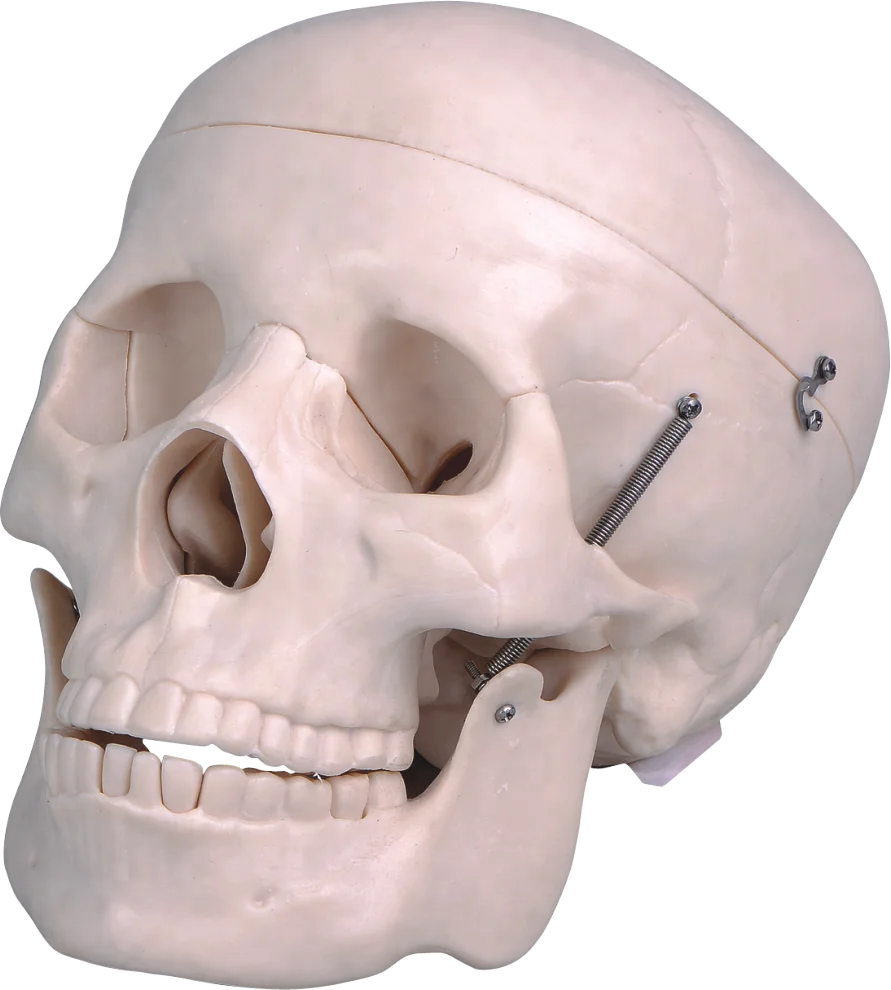

Human skull Human skull |

32 hours |

Modularity

If your design will be too large for the printer’s build volume, you may want to consider modularity; this involves printing the model in separate parts, combining them after to make up the complete model. This can be done after the model is designed, but you may want to design with this in mind. Software is available to help break up your model into parts, such as Slicer.

Unit conversion

The Ultimaker printers and their accompanying software, Cura, use the metric system of measurement. If at all possible, we suggest that you design your model using millimetres rather than inches. In some cases, designing in inches can result in a much larger than expected finished product. If designing in mm is not possible, you may need to adjust the model’s size to accommodate.

Fine Details

Fine detailing on a 3D model can be tricky to print with the Ultimaker printers. Because the printer creates its models by heating up plastic and spitting it out of a small hole in the extruder’s nozzle, the level of detail is limited by the diameter of the nozzle’s hole. The Makerspace’s Formlabs printer is typically better suited for printing intricate models with fine details.

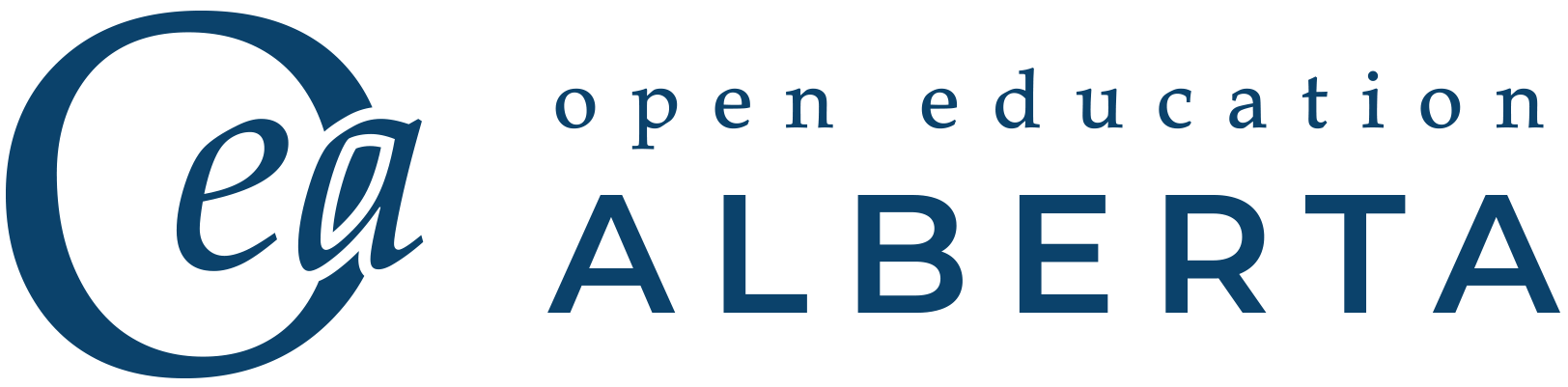

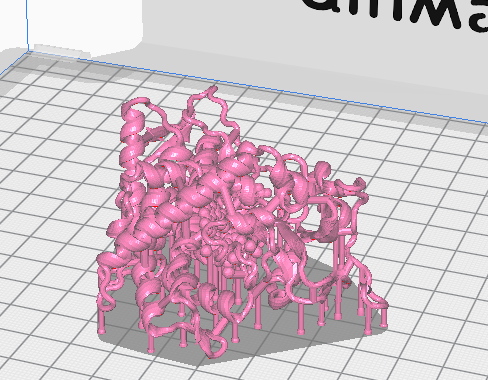

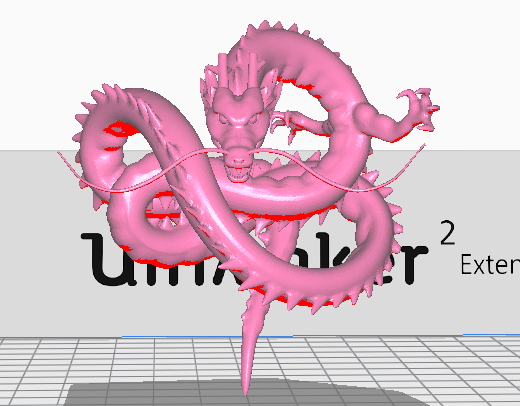

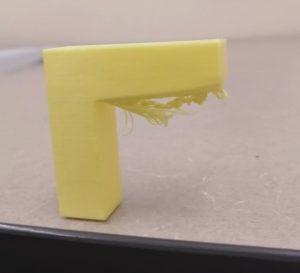

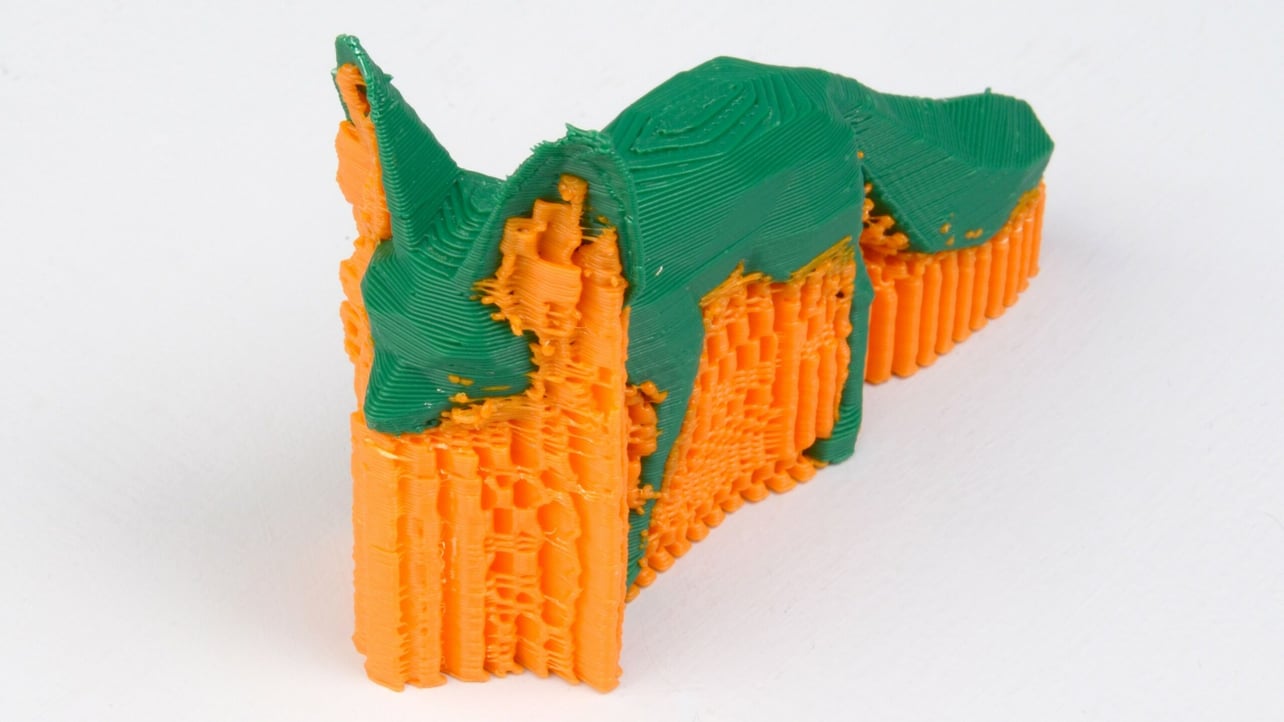

Here are some examples of models that will probably not print very well using the Ultimaker printers:

- Image 1

- Image 2

- Image 3

Overhangs

Most of the 3D printers in our makerspace create physical models by laying down thin strips of melted plastic (filament), one layer at a time, to create a finished model. If the machine attempts to print a line of filament in a place where there isn’t a printed line of filament to support it, the printer will print into mid-air and create an undesirable effect.

As a general rule, 3D printers should be able to print a 45 degree overhang; however, consider anywhere on your model where overhang exists and consider how that may impact the model. In the next chapter we will cover “supports” which are used help print models with more than a 45 degree overhang.

Bed Contact

The success of your printed design could depend on the reliability of the model’s bed contact. The smaller the point of contact between the design and the print-bed, the more likely the model could topple over during printing.

Most 3D printing software can help accommodate small points of contact by adding material in the first few layers. The most common of these tools are called skirts and brims. We will discuss skirts and brims in the following chapter, but in the meantime, it is worth considering your model’s point of contact on the print bed.

H5P test:

Exercises

References

Carolo, L. (2020, November 15). Best 3D Printer Nozzle – Buyer’s Guide. All3D. https://all3dp.com/2/3d-printing-overhang-how-to-master-overhangs-exceeding-45/

Image 1. Sokamarintchak. (2016, May 4). CYP1A2 (Cytochrome P450 1A2). Thingiverse https://www.thingiverse.com/thing:1540639

Image 2. Rubaxx. (2018, August 31). Shenron. Thingiverse. https://www.thingiverse.com/thing:3077771

Image 3. Hyla. (2013, September 13). Sinus Veins. Thingiverse. https://www.thingiverse.com/thing:150173

Kondo, H. (2021, June 16). 3D Printing Overhang: How to 3D Print Overhangs. All3dp. https://all3dp.com/2/3d-printing-overhang-how-to-master-overhangs-exceeding-45/

Krishnan, A. (2020, July 29). Design for FFF 3D printing: Maximize your success. Ultimaker. https://ultimaker.com/learn/design-for-fff-3d-printing